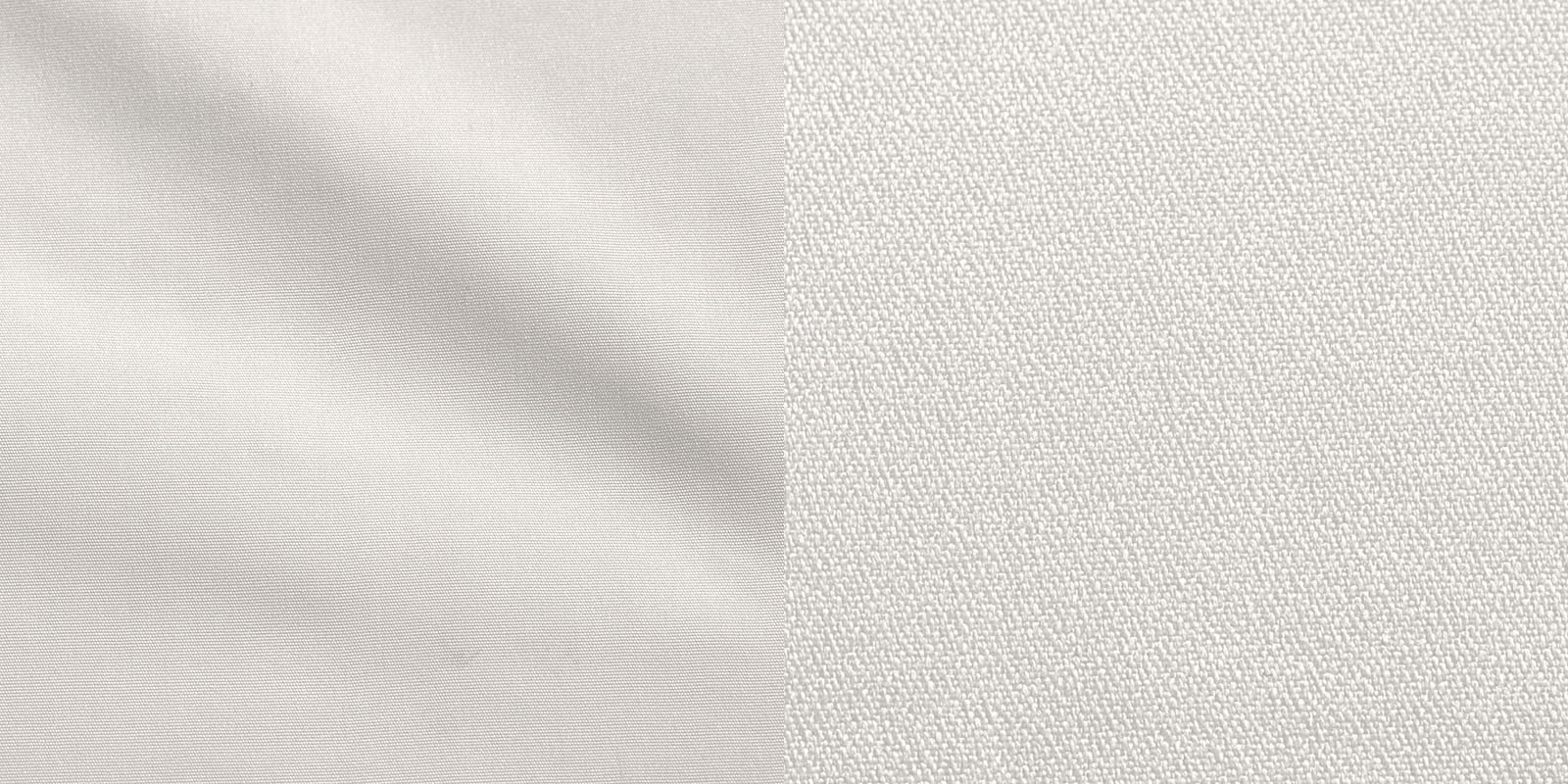

Those who have used clean cloth will know that the texture of clean cloth is divided into straight grain and net grain, but many people have such doubts, what is the difference between straight grain and net grain? Will there be any difference in the use effect, the quality of the clean cloth, and the service life? Today we come to understand the difference.

The difference between straight-grain and net-grain clean cloth, from the perspective of the different weaving methods, the straight-grain looks like a straight strip, the structure on both sides is the same, and it is more wear-resistant. The net looks like a net, but the net The decontamination effect is better. There is not much difference between the two, but the straight-grain clean cloth will feel more delicate, and the net-grain clean cloth is slightly rougher. Therefore, the cleanliness of the net-grain clean cloth is better, and the straight-grain clean cloth will have less abrasion on the product, and the difference is not big. Many industries in the market now use dust-free cloths, and dust-free cloths are also extremely versatile.

There are four types of clean cloth

1. Knitted wipes: Continuously knitted by superfine fibers.

2. Woven wipes: woven from natural, mixed or natural or mixed fibers on a loom.

3. Foam wipes: PU is chemically processed to expand into a large structure, and then cut into foam wipes of various shapes and sizes.

4. Non-woven ultra-fine fiber dust-free cloth: It is made of woven short fibers or filaments that are oriented or randomly arranged to form a fiber network structure, and then reinforced by mechanical, thermal bonding or chemical methods.

But pay attention to when using and unpacking, you need to wear dust-free gloves and masks, although it has good water absorption and cleaning efficiency, but also pay attention to the place where it is applicable, don't make a fuss.

Which one is better, straight grain clean cloth or net grain clean cloth? In fact, this depends on the actual application and whether it is suitable for use. Specifically, it depends on your actual cleanliness requirements for the product, which is also a necessary determinant for purchasing clean cloth.

If we want to judge whether the clean cloth is good or bad, we all hope to buy a clean cloth of very good quality, but the reality is often unsatisfactory, so how should we judge the clean cloth when buying The quality of the dust cloth? Everyone judges the quality of clean cloth from the following three aspects.

Choice of clean cloth

1. Basis weight: Is the basis weight of the same fabric the same?

2. Type and quality: Superfine fiber has higher quality and polyester fiber is lower

3. Softness: the softer the better

4. Abrasion resistance: the stronger the fiber, the less fiber will be lost

Different edge banding methods of clean cloth

1. Laser cutting: The edge banding degree reaches 99%, no chips, no dust, the highest technology and cost

2. Ultrasonic cutting: The edge banding degree is below 80%, no chips, and the edge banding is easy to tear and chip off after cleaning.

3. Thermal cutting: the degree of edge banding is less than 75%, no chipping, and the edge banding is easy to tear and chip off after cleaning

4. General cold cutting: unsealed, easier to chip off, lowest technology and cost

Clean cloth quality inspection

1. Whether there is an inspection report from the certification unit

2. Ion content: Is it within the range of the reference test standard

3. Water absorption: whether it meets product requirements

4. Wipeability: the stronger the better

5. Dust generation: the lower the better