In recent years, the clean cloth consumables market has been very popular in the market and has broad prospects due to its close proximity to the world's hottest industries-LCD screens, semiconductors, LCDs, and PCBs.

In such a broad market prospect of clean cloth, if a professional trader (purchaser) of purification consumables does not understand the professional purchasing knowledge of clean cloth, how can you explain the advantages of the product to customers in the future? How to provide customers with the best product selection? Or how to provide customers with better and better cost-effective services?

If you want to know something about dust-free cloth, you can't just use the name, touch and other surface information to estimate the scope of use of the product, but must analyze the product structure and production principle to finally understand the physical of the product Performance in order to better recommend products for customers.

Today I will share with you about the correct choice of microfiber clean cloth. At present, there are two main types of weaving processes for microfiber dust-free cloth in the market:

The first type is knitted microfiber clean cloth

Knitted microfiber dust-free cloth is knitted and woven with polyester and nylon composite microfiber dual machine.

The second type is woven microfiber clean cloth

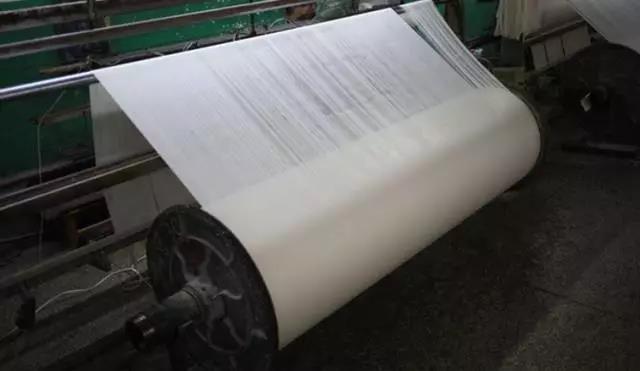

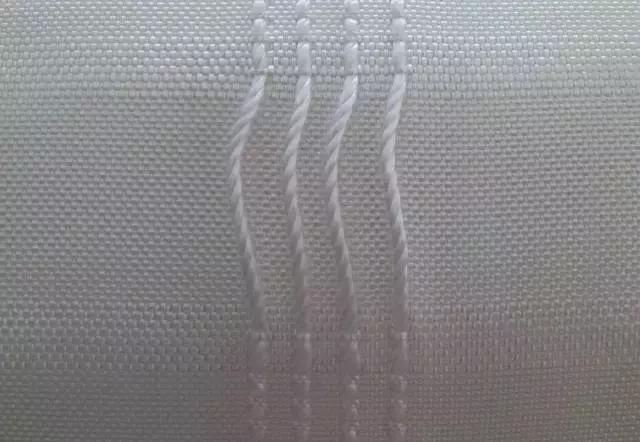

The woven superfine fiber dust-free is woven with polyester and nylon composite superfine long fiber.

The weaving method of knitted microfiber dust-free cloth is to use needles (Needle) to bend one or several yarns fed from the weft direction into a series of loops (Loop), and then combine the new loops generated this time with The old loops generated last time are looped together to form a knitted fabric (Knitting Fabric).

The weaving method of woven microfiber dust-free cloth consists of two mutually perpendicular yarns, which are interlaced up and down according to a certain rule to form a fabric called woven fabric (woven fabric). In fabrics, the yarns along the length of the fabric are called warps. The yarns along the width of the fabric are called wefts. The interweaving law of warp and weft is called fabric weave.

The biggest advantage of the knitting process is that it can be stretched in all aspects, has good elasticity, has a very good touch feeling, and has good air permeability. According to the physical and mechanical properties of longitudinal density, transverse density, square meter weight, elongation, elasticity, breaking strength, abrasion resistance, etc., customers can choose products with high adaptability.

The advantage of the weaving process is that due to the tightness of the fibers, the abrasion resistance of the microfiber dust-free cloth becomes stronger, and its proper hardness can also help to wipe stubborn stains thoroughly. The pros and cons of woven microfiber dust-free cloth can be selected based on its warp and weft yarn density, wear resistance, fabric coverage and other physical and mechanical properties.