Superfine fiber introduction:

Superfine fiber yarn is a non-polluting high-tech new textile material, the composition of which is an ultrafine microfiber produced by the organic compound of polyester and nylon. Because it is a kind of raw material with remarkable functions such as strong water absorption, good air permeability, anti-mildew (it can also be anti-bacterial and anti-bacterial after being processed by special process). The ultra-fine fiber towels are made of imported polyester-nylon particles. The polyester-nylon composite ultra-fine fiber yarn is standard 8020 high-quality polyester-nylon composite yarn. 300, 1 gram of ultra-fine fibers, ultra-fine fibers are stretched 90,000 meters without breaking).

Due to the extremely fineness of the ultrafine fiber, the rigidity of the silk is greatly reduced, and the fabric feels extremely soft. The thin fiber can also increase the layered structure of the silk, increase the specific surface area and capillary effect, and make the reflected light inside the fiber more distributed on the surface. , So that it has a silky elegant luster, and has good hygroscopicity.

Material composition:

Superfine fiber, also known as microfiber, fine denier fiber, ultrafine fiber, English name microfiber. The components are mainly composed of polyester polyester and nylon polyamide (domestic is generally 80% polyester 20% nylon, and 100% polyester (poor water absorption effect, poor feel)). The fineness (that is, the thickness) of general chemical fibers is mostly between 1.11 ~ 15 deniers and the diameter is about 10 ~ 50 microns. The fineness of the ultrafine fibers we usually talk about is between 0.1 ~ 0.5 deniers and the diameter is less than 5 microns. The fineness is 1/200 of the hair silk, 1/20 of the ordinary chemical fiber, the fiber strength is 5 times (durability) of the ordinary fiber, the adsorption capacity, the water absorption speed and the water absorption are 7 times the ordinary fiber.

The biggest feature of microfiber fabrics is that microfibers have many fine gaps between microfibers, thereby forming capillary structures, which are processed into towel fabrics. They have the characteristics of super water absorption, fast water absorption, and high water absorption. It can carry more than 7 times its own weight of water, the water absorption rate is equivalent to 7 times that of ordinary fibers, and the fiber strength is 5 times that of ordinary fibers (durability), so the water absorption of microfiber towels is far superior to other fabrics .

The microfiber has a capillary structure and a large surface contact area, so the coverage of the microfiber fabric is extremely high, the surface of the microfiber is in contact with dust or oil more often, and the oil and dust from the microfiber There are more opportunities to penetrate the gap, so the microfiber has a strong decontamination and cleaning function. The microfiber towel can penetrate deep into the pores of the skin and effectively remove dirt, oil, dead skin, and cosmetic residues on the body surface to achieve beauty. The effect of body cleansing.

Due to the small diameter of the microfiber, its bending strength is very small, and the fiber feels particularly soft. The seam between the microfibers is between the diameter of the water droplets and the diameter of the water droplets, so the microfiber fabric has the effect of waterproof and breathable , And can overcome the shortcomings of natural fibers such as easy to wrinkle, man-made fibers are not breathable, durability is more than five times that of ordinary fabrics, using ultra-fine fibers processed into bath towels, bath skirts, bathrobes, the human body is softer and more comfortable, care for the delicate body skin.

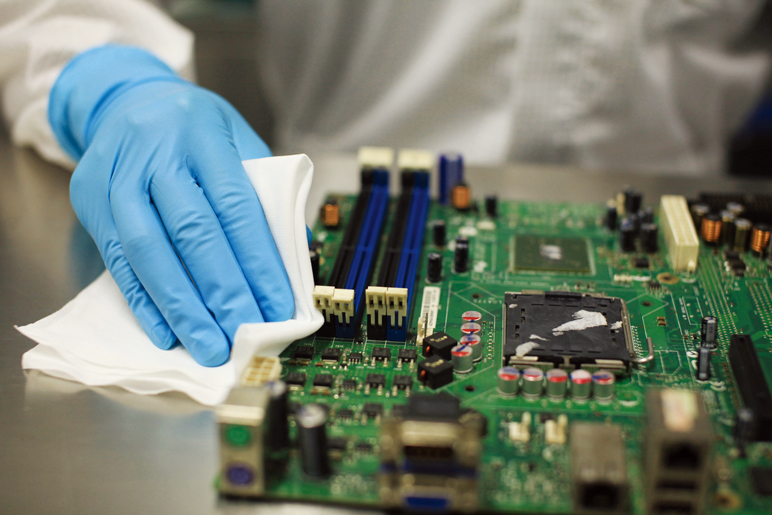

Superfine fiber is not only used in people's home life, but also widely used in various industries such as industry, workshop, car maintenance, mulberry bath hotel, beauty salon, sports goods, daily necessities, shopping mall office cleaning and so on.

Performance characteristics:

High water absorption: The ultra-fine fiber uses orange petal technology to divide the filament into eight petals, which increases the surface area of the fiber and increases the pores in the fabric. The capillary wicking effect is used to enhance the water absorption effect. It absorbs water quickly and dries quickly as its distinguishing characteristics.

Strong detergency: The fineness of microfibers with a diameter of 0.4μm is only 1/10 of silk. Its special cross-section can more effectively capture dust particles as small as a few microns. The effect of decontamination and degreasing is very obvious.

No hair removal: High-strength synthetic filaments are not easy to break. At the same time, the fine weaving method is adopted, and the fibers are not easy to fall off from the surface of the towel. It is used to make cleaning towels and car towels, which are particularly suitable for wiping bright paint surfaces, electroplated surfaces, glass, instruments and LCD screens. When the glass is cleaned in the process of automobile filming, it can achieve a very ideal film effect.

Anti-mildew and long life: due to the strength and toughness of ultra-fine fibers, its service life is more than 4 times the service life of ordinary towels, and it remains invariable after multiple washings. At the same time, polymer polymer fibers will not look like cotton fibers That produces protein hydrolysis, even if it is not dried after use, it will not mold, rot, and have a long life.

Easy to clean: When using ordinary towels, especially natural fiber towels, the dust, grease, dirt, etc. on the surface of the object are directly absorbed into the fiber. They remain in the fiber after use and are not easy to remove. Even after a long period of use Will harden and lose flexibility, affecting use. The ultra-fine fiber towel absorbs dirt between the fibers (not inside the fibers). In addition, the fiber has a high fiber density and high density, so the adsorption capacity is strong. After use, only clean with water or a little detergent.

No color fading: the dyeing process uses TF-215 and other dyes for ultra-fine fiber materials, and its retardation, migration, high temperature dispersibility, and decolorization indexes have reached the strict standards for export to the international market, especially its colorfastness. The advantage of it is that it will not bring the trouble of discoloration and pollution when cleaning the surface of the article.