The clean cloth market is now broad. As a professional buyer or salesperson of microfiber clean cloth wholesale manufacturers, if you do not understand the structure and principle of microfiber clean cloth, you do n’t know how to purchase or tell customers. Products, if you want you to understand the microfiber dust-free cloth, you can not only stay on the superficial surface, but to understand and recognize it from the internal structure of the microfiber dust-free cloth structure and working principle. Don't look at the tiny microfiber dust-free cloth, there is a lot of knowledge in it.

The structure of microfiber dust-free cloths on the market can be divided into the following four methods: knitted wipes, woven wipes, foam wipes, non-woven microfiber clean cloths

1. Knitted wipes: made by continuous knitting of ultra-fine fibers.

2. Woven wipes: made of natural, mixed or natural, mixed mixed fibers on the loom.

3. Foam rag: PU undergoes chemical processing to expand into a bulk structure, and then cut into foam rags of different shapes and sizes.

4. Non-woven ultra-fine fiber dust-free cloth: It is made of woven staple fibers or filaments oriented or randomly supported to form a web structure, which is then reinforced by mechanical, thermal bonding or chemical methods.

Dust removal principle of microfiber dust-free cloth:

A. Multiple scraping effect: A single thick fiber can be converted into hundreds of ultra-fine fibers by ultra-fine, so when used as a cleaning cloth, the ultra-fine fibers can be scraped more than ordinary wipes effect.

B. Wide contact area effect: Generally, because the fiber is thicker and the bending rigidity is large, the contact area of the fabric floating point and the object is small. On the contrary, the ultra-fine fiber has a small bending rigidity and is soft (like silk). Large contact area and strong cleaning power.

C. Internal peeling effect: The wipe cloth made of ultra-fine fibers will migrate outward along the capillary channel of the fiber after scraping off the dirt, showing an internal peeling effect, so that the dirt will not remain in Wipe the surface of the cloth, so it will not cause scratches for extremely precise products.

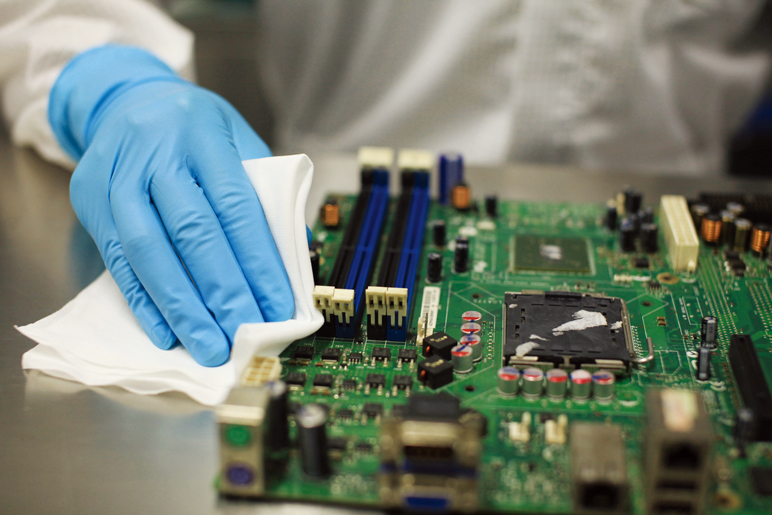

What are the main uses of clean cloth? The dust-free cloth is mainly used for wiping conductor production line chips, microprocessor assembly production lines, etc .; LCD liquid crystal display products and circuit board production lines, etc .; precision instruments, optical products, aviation industry, etc. Because the dust-free cloth is double-woven with 100% polyester fiber, the fiber diameter is very small, so its bending stiffness is very small, the hand is particularly soft, it is easy to wipe sensitive surfaces, and the fiber is not removed by friction. It has good water absorption and cleaning efficiency. Therefore, the application of dust-free cloth in these industries has a very obvious effect, and the dust-free cloth can be used repeatedly after being properly cleaned!