With the development of science and technology and the progress of society, people have higher and higher requirements for the cleanliness of work or environment in work and life. Especially in industry, the requirements for cleaning dust and oil on the surface of the machine and the processed workpiece are becoming higher and higher.

Depending on the precision of the items being wiped, the requirements for wipes are also different. In industry, the most widely used are cheap cotton yarn, rag heads, rags, etc., but industrial wipe paper, industrial wipes, etc. that are professionally used for cleaning are rarely used.

For some workstations that require high cleanliness, general wipe cloth, cotton yarn, etc. can no longer meet the needs of manufacturers. The industrial-specific wipes developed for the supply of dust-free protective consumables can be successfully used in machine repairs including auto repair, aircraft, precision equipment and other industries.

The cleaning work in the industrial field is closely related to product production and product quality.

Whether it is the water stains and oil stains on the mechanical equipment or products in the production workshop, or the chemical reagents on the instruments in the laboratory and research room, timely and efficient cleaning and hygiene are required to ensure the effective work.

But how to judge whether the industrial wipes you choose are easy to use?

01 | Efficient water and oil absorption capacity

There are many places where wipe paper is needed in industrial occasions, and most of them are because of dripping or leaking oil or water stains. The wipe paper used at this time requires strong absorption capacity to ensure the smooth completion of the work.

02 | Good compatibility with solvents

In the industrial production process, the machine or product may be stuck with a chemical solvent that is difficult to clean. At this time, cleaning requires that the equipment to be wiped is well fused with the solvent to be fully cleaned.

High-quality industrial wipes blend well with solvents to deeply clean stains and protect your hands from heat and metal scraps.

03 | Not easy to leave dust after wiping

Working instruments, especially glass instruments and instruments in production laboratories and research rooms, need to be very careful when cleaning and wiping after sticking oil and chemical reagents, so they have high requirements for the quality of cleaning equipment.

If it is easy to leave dust, etc., it will not only damage the appearance of the product, but also affect the quality of the product.

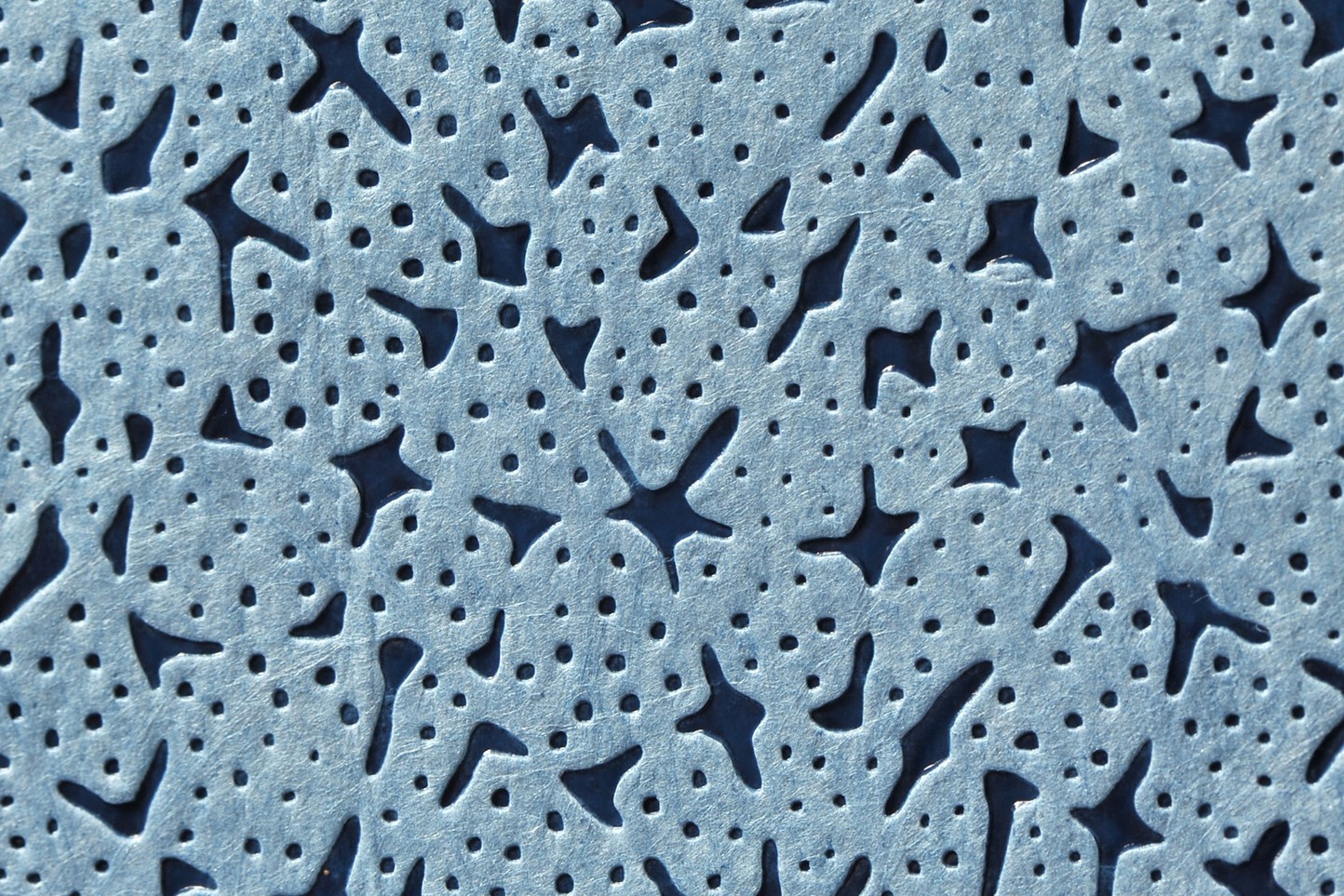

The high-quality industrial wiping cloth is made of polyester fiber, chemical pulp and other raw materials. After wiping, it is not easy to leave hair debris and complete the highly demanding surface cleaning tasks.