1. Market Overview

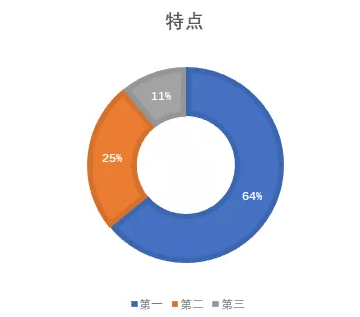

After more than ten years of development, China has become a major producer of spunbond nonwoven fabrics, and its overall hardware and equipment have been greatly improved from a few years ago. In China's spunbond nonwovens industry, technical equipment mainly comes from three different channels, forming distinct characteristics:

First, domestic non-woven material equipment manufacturers. The domestic spunbond nonwoven equipment is mainly imitation, the project investment is small, the manufacturing process is not good enough, the equipment failure rate is high, but the enterprise product structure adjustment and independent technical transformation have greater flexibility, and the enterprise can meet the changing needs of the market , Through the technical transformation and upgrading of equipment to develop new technologies and new products, so as to meet the needs of differentiated product production.

Second, import production equipment from abroad and provide a relatively single variety of production technology. Because the production variety is relatively single, it is conducive to the control of production costs; the mechanical operation is stable and the failure rate is low, the production speed is fast, and the product quality is guaranteed; but it is not easy to implement flexible product structure adjustment, it is difficult to form a unique core technology process, and the enterprise differentiates products The competitiveness is weak, and the enterprise's ability to resist risks is poor.

Third, the enterprise specializes in customizing equipment according to its own technological characteristics and product strategy. Enterprises configure specific production lines according to their own process technology or specific product markets, and selectively purchase various models during the configuration of production lines. Specialized customized equipment requires the company to have rich industry production management experience and to have the relevant software and hardware development capabilities. At present, there are only a few domestic enterprises that have the ability to professionally customize equipment, and can participate in differentiated and high-end product market competition through their own core process technology.

2. Industry development pattern

In recent years, the development of China's spunbond nonwovens industry has mainly focused on the expansion of production capacity and quantity. Most enterprises in the industry are small in scale and weak in technology research and development. They mainly rely on foreign production line equipment to produce a large number of low-end homogeneous products As the main means of competition, price is in a state of complete competition in the industry, and its ability to resist market risks is weak. With the gradual improvement of people's pursuit of quality of life and the rapid expansion of downstream applications of spunbond nonwovens, traditional low-end spunbond nonwoven products will not be able to adapt to rapidly changing market demands. This will promote the integration of the industry in the entire industry, which will gradually eliminate small and medium-sized enterprises with backward technology and weak financial strength, gradually increase industry concentration, and optimize the overall structure of the industry.

Secondly, the differentiation of enterprise development in the industry has initially appeared, and a few excellent enterprises have stood out. In recent years, with the development of the industry, advantageous enterprises in some industries, including Zhejiang Jinsan and Jinjiang Xingtai, have accelerated their development by virtue of their advantages in scale, capital, technology and operation, focusing on the mining of production processes, products The expansion of categories and the improvement of product quality have enabled a small number of enterprises including Zhejiang Jinsan and Jinjiang Xingtai to establish a good reputation and brand influence in the industry.

3. Industry development characteristics

(1) Regionality of the industry

Spunbond nonwoven fabrics have the characteristics of large volume, light material, and high transportation costs over long distances. Therefore, the sales of enterprises in the spunbond nonwoven fabric industry will be subject to certain regional restrictions due to transportation conditions and transportation distance constraints. In addition, in view of the fact that the raw materials of spunbond nonwoven fabric companies are mainly polyester and polypropylene, their production sites are often close to the raw material supply places. At present, China's spunbond nonwoven fabric companies are mainly concentrated in Zhejiang, Jiangsu, Fujian, Shandong and other regions.

(2) The periodicity of the industry

The spunbond nonwovens industry provides raw materials for the production of downstream end-customer products, and the periodicity of the industry is closely related to the periodicity of the industries where the major downstream customers are located.

At present, the downstream application fields of spunbond nonwoven fabrics are extensive, mainly used in civilian, medical and health fields for the daily consumption of end consumers. The purchasing power and willingness of end consumers determine the spunbond nonwoven fabrics located in the middle of the industrial chain Industry development.

In the short term, the spunbond nonwoven industry is not very cyclical. In the long run, with the growth of the global economy, people's living standards have gradually improved, and the overall demand for products has shown a steady growth trend. Therefore, in the long run, the spunbond nonwoven industry The periodicity of the economy is basically the same as the overall economy.