Different packaging materials have different bacteriostatic effects, and different bacteriostatic effects come from their different bacteriostatic principles. Therefore, we summarize the bacteriostatic principles from two aspects of 'pore size' and 'weight'.

Principle of gas permeable packaging materials: the gas permeable packaging materials are generally controlled by the size of the pore diameter, and the packaging microorganisms will not invade. At the same time, the effect of gas permeable packaging materials can be achieved by multi-layer filtration.

The traditional principle of cotton cloth resistance to bacteria: the pure cotton cloth can only be used when it is made of 140 yarns (80 yarns are mainly produced in China). Its resistance to bacteria mainly depends on the pore size to achieve the purpose of resistance to bacteria, so the effective period of resistance to bacteria is relatively short (about 7 days).

Antibacterial principle of non-woven fabric material: as a non-woven fabric for aseptic packaging, it is required to have three layers. The middle melt spraying layer and the inner and outer spunbond layers are composed. It mainly depends on the pore size of the melt blown layer and the spunbond layer to achieve the bacteriostatic effect and ensure the sterile state (which can reach 180 days of sterile validity).

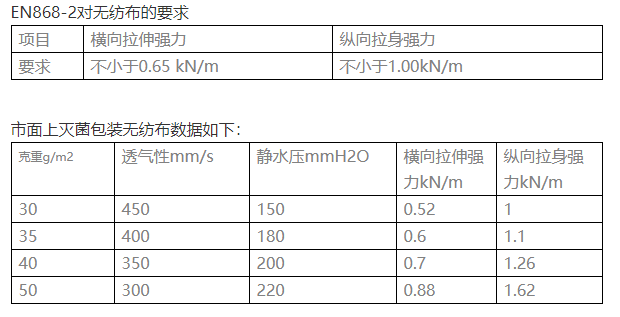

The effect of gram weight on bacteria resistance of nonwoven materials:

Influence of weight per unit area on sterilization package itself:

1. Easy to be damaged. When the gram weight is not enough (the sense is relatively thin, and the distribution of light transmittance is uneven), the tensile strength of the non-woven material itself is not enough, and the non-woven fabric is easy to be punctured.

2. The fibers on the surface are easy to fall off. The weight is too light, the spunbond layer is too thin, and the melt blown layer cannot be covered well, resulting in fiber falling off, and finally the pipeline and filter screen of the equipment are blocked, resulting in sterilization failure.

3. The weight is too small, and the static water pressure resistance of the non-woven fabric is too low. The pore size of hydrostatic reaction directly affects the inhibition effect.

As a non-woven fabric of aseptic packaging, it should meet the following requirements: excellent air permeability, tensile strength and hydrostatic pressure of at least 340mm water column. Requirements for antimicrobial packaging materials: effective, safe and risk-free

From the above data and en868-2 requirements comparison, if the weight is less than 35g, it can not be used as sterilization packaging materials; in addition, it is considered as a safe and effective factor for sterilization.

According to the comparative data, it is suggested to use non-woven fabrics with a weight of more than 40g as the sterilization packaging materials. Our company's sterile pre soaked wiping cloth, multi-functional wiping cloth, super energy wiping cloth and other products are processed with materials of 50g or more, which greatly enhances the antibacterial effect.