The traditional raw materials of wiping products are mostly old cloth, textile mill leftover, etc., which come from confusion, unstable quality, inconsistent size, poor water absorption and oil absorption, easy to fall off dust and fade color, no fixed packaging, low wiping efficiency, high labor cost, and easy to damage equipment and product surface.

Dust free wiping cloth is a kind of cleaning and wiping material widely used in electronic, optical, biological, medical and other fields. According to the cloth, dust-free wiping cloth can be divided into polyester cloth, microfiber cloth, cotton cloth, non-woven dust-free cloth (dust-free wiping paper), etc.

The cotton fiber non-woven fabric is made of 100% pure cotton and developed by special processing with pure natural raw materials (see Fig. 2-4 for the structure picture of cotton fiber). It has super hygroscopicity, moisture retention, antistatic, long fiber and no adhesive. High temperature resistance is good, generally in 260-300 degrees. It is not only environmentally friendly but also has excellent performance. It is mainly used for equipment maintenance and general wiping requirements of products in high-level controlled environment.

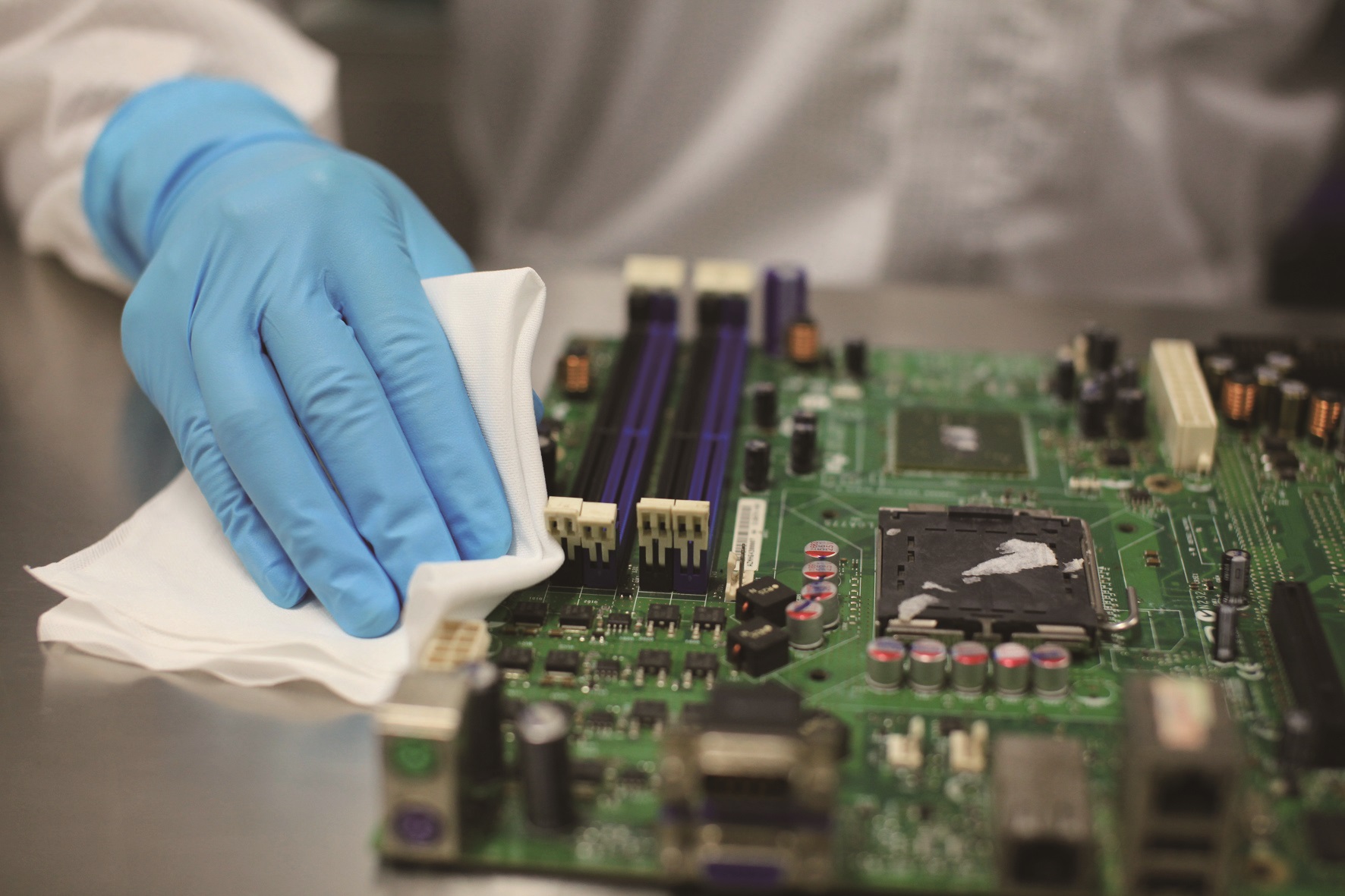

The surface of the dust-free cloth is soft, easy to wipe sensitive surface, without dropping the scurf, with good cleanliness and water absorption. And the cleaning and packaging of the products are completed in the dust-free workshop. It is the most effective cleaning tool in the clean room.

For the current changing industrial demand, there are different grades and specifications of dust-free cloth. For example, liquid crystal wiping cloth, chip wiping cloth, CD wiping cloth and battery wiping cloth, etc.